Xarunta Mashiinka ee CNC waxaa la odhan karaa waa isku-dhafka hawlaha mashiinka.Xarunta Mashiinka ee CNC waxay dabooshaa awoodaha farsamaynta ee kala duwan.Wax-soo-saarka hal-joojin wuxuu yareeyaa wakhtiga beddelka mashiinka waxayna hagaajinaysaa waxtarka wax-soo-saarka.

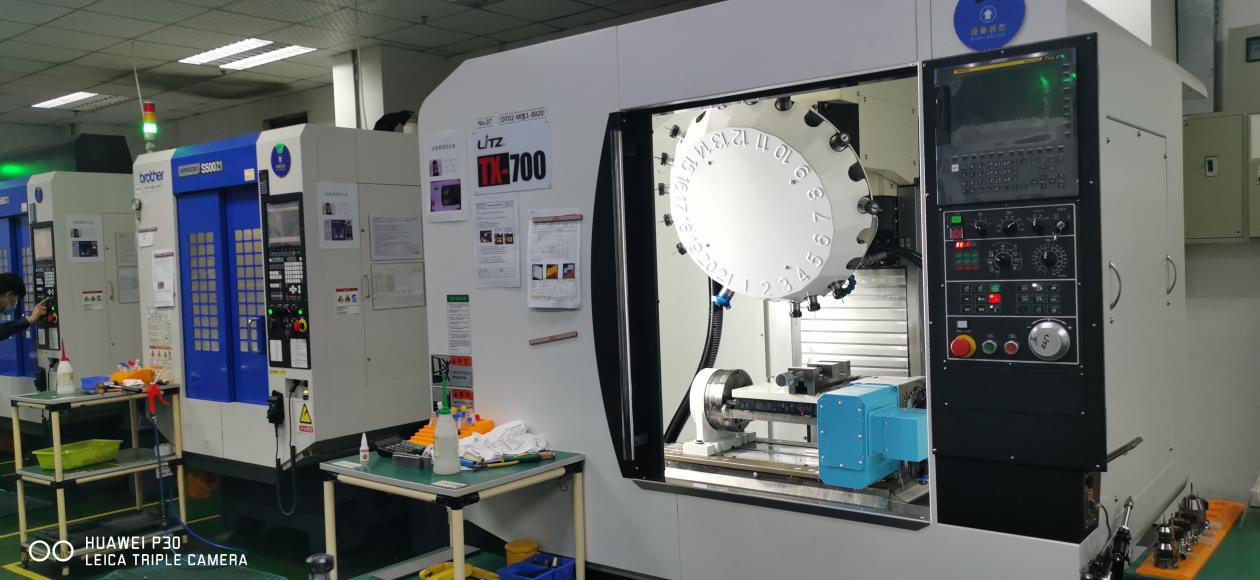

Xarunta mashiinka CNC waa qalab wax soo saar horumarsan.Mashiinadu waxay qaban karaan hawlo farsamo oo kala duwan.Noocyada iyo shaqooyinka Xarunta Mashiinnada CNC ayaa lagu soo bandhigay hoos.

Xarunta mashiinka CNC waa mashiinka wax soo saarka ee horumarsan kaas oo fulin kara hawlo farsamo oo kala duwan oo sax ah, tayo sare leh, oo dhammaystiran oo sarreeya.Xarunta qalabka mashiinka CNC waxay fulin kartaa qodista, wax-shiidka, iyo wax-soo-saarka.

Soo saarista qaybaha prismatic ee warshadaha, sida sanduuqyada gearboxes, partitions, frames, covers, iwm, waxay u baahan yihiin noocyo kala duwan oo hawlgalo ah sida shiididda, caajiska, qodista, tuubada iyo hawlo kale oo badan oo mashiinada la xidhiidha.Waagii hore, habkan wax-soo-saarka waa in loo qaybiyaa qaybo badan oo shaqo ah, iyo hawlgalka qalabka mashiinka kala duwan ayaa awood u leh inuu soo saaro badeecad dhamaystiran, taas oo keentay qadar badan oo wakhti iyo kharash ah.Si looga gudbo dhibaatadan, xarunta qalabka mashiinka CNC ayaa la sameeyay.Dhaqdhaqaaqa, dhaqidda, iyo qodista hal mashiin waxay u oggolaanaysaa hal mashiin inuu fuliyo baahiyo farsamo oo kala duwan.

Nooca makaanikada ee xarunta mashiinka CNC:

Ujeedada ugu weyn ee xarunta mashiinka CNC waa in la yareeyo waqtiga wax soo saarka iyo hababka horumarsan ee xarunta mashiinka CNC.

● ATC (qalabka beddelka tooska ah)

● APC (beddeli palette toos ah)

● Nidaamka adeegga CNC

● Nidaamka jawaab celinta

● Dib-u-wareejinta kubbadda kubbadda iyo lowska

Nooca qaabaynta ee xarunta mashiinada CNC:

● Xarunta Mashiinada Horizontal

● Xarumaha Mishiinada Toosan

● Xarumaha Mashiinada Caalamiga ah

1.Horizontal Machining Center

Xarunta mishiinada waxa ay leedahay dunta isdifaaca oo toosan, qalabkuna waxa uu ku rakiban yahay dunta mishiinka, inta badan waa mishiin qudha oo leh qalab beddela oo toos ah.ATC-gu waxa uu ka kooban yahay joornaal la bedeli karo oo kaydin kara qalabyo kala duwan oo haysta ku dhawaad 16 ilaa 100 qalab.Si loo dhimo wakhtiga rarista iyo dajinta, waxa lagu rakibi karaa bedeliyaha palette ee tooska ah (APC).APC waxay ka kooban tahay lix, sideed ama in ka badan palette, workpiece waxaa lagu dhejin karaa palette ah, iyo mishiinka waxaa loo qorsheeyay si ay u dhamaystiraan pallet hore.Ka dib markaad shaqeyso, beddel saxaarad kale oo cusub.Barnaamijyo kala duwan ayaa laga yaabaa in looga baahdo qaybo shaqo oo kala duwan.Sababtoo ah heerka sare ee ka saarista walxaha ee habka, mugga qalabka wax lagu gooyo badanaa waa weyn yahay, sidaas darteed joornaalka qalabku wuxuu u baahan yahay meel weyn oo qalab kasta ah, iyo miisaanka qaraabada ayaa sii kordhaya.Qaar ka mid ah qalabka mishiinada ayaa sidoo kale leh hawlo dheeraad ah si ay u wareegaan dunta oo dhan si ay dhidibka jiifka ah ee duntu u noqoto mid toosan, taas oo u oggolaanaysa farsamooyin hawleed oo kala duwan.

2.Xarunta Mashiinada Tooska ah

Mashiinka noocaan ah, shaqooyin badan ayaa lagu qaban karaa hal qalab.Inta badan xarumaha makiinadaha toosan waxay leeyihiin saddex faas, qaarna waxay leeyihiin shaqada madaxa dunta oo lagu rogman karo hal ama laba faas.Si loo farsameeyo dusha sare ee xaradhka, xarunta farsamaynta toosan ayaa ugu habboon warshadaynta caaryada iyo caaryada.Noocyada ugu muhiimsan ee xarumaha mashiinada toosan waa sida soo socota: tiirarka socodka, qaababka gantry, iyo lafdhabarta badan.

3.Universal Machine Center

Xarunta mishiinada caalamiga ah waxay la mid tahay xarun mashiineed toosan, laakiin usheeda dhexe si joogto ah ayaa looga leexin karaa meel toosan oo loo jeediyo meel toosan oo kombuyuutarku gacanta ku hayo.Xarunta mashiinka caalamiga ah waxay ka kooban tahay shan ama in ka badan oo faas ah oo u oggolaanaya dusha sare ee shaqada in lagu dhejiyo xarun farsamo oo siman si dhinacyada kala duwan ee shaqada loo mariyo hal cutub.

Waqtiga boostada: Mar-04-2022